The team demonstrated exceptional flexibility, efficiently transitioning from conceptualization to the creation of manufacturable designs. The collaborative effort extended to engaging with factory contacts, ensuring seamless production processes.

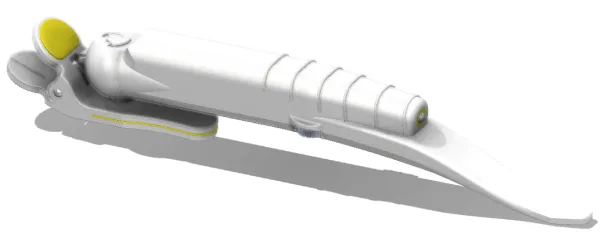

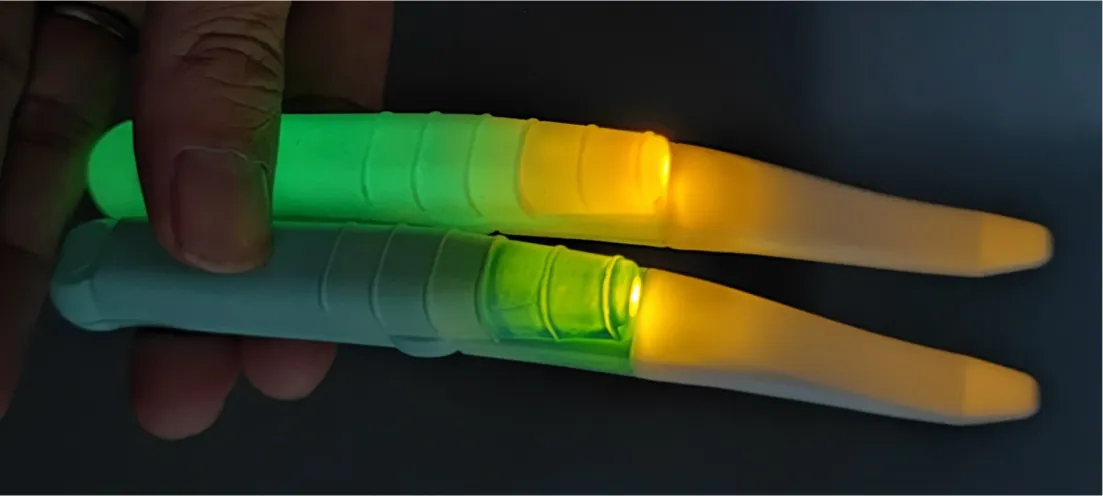

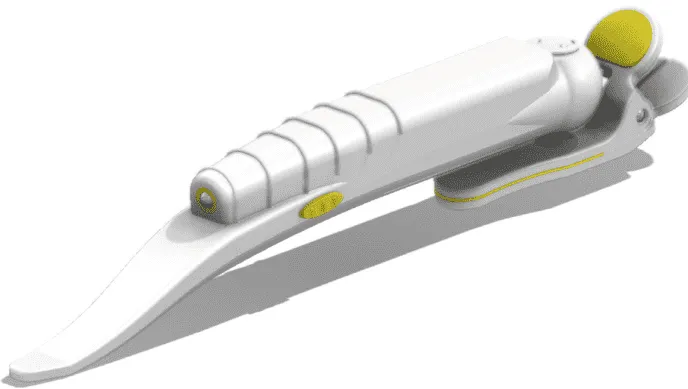

This custom consumer product was designed as a flashlight for nursing mothers to wear and use while feeding their babies at night. The removable silicon tip is used as a utensil for nursing mothers to manipulate and correct their baby’s latch The product’s design was optimized for plastic injection molding and features several silicon and silicon overmolded components to ensure water resistance and washability for reuse. The LED was carefully selected to be soothing at night, and a battery was selected for optimal battery life and form factor.

Latch Light approached us with a product that had been developed in collaboration with an overseas factory. They were unhappy with the quality of the design work and samples. They needed a redesign to address their specific needs and a set of production files with complete ownership to shop different potential manufacturers.

Latch Light’s original design, produced in collaboration with overseas factories, had several problems with it. Latch Light brough in Emergnt to address these issues.

Latch Light wanted to improve the following aspects of their previous samples:

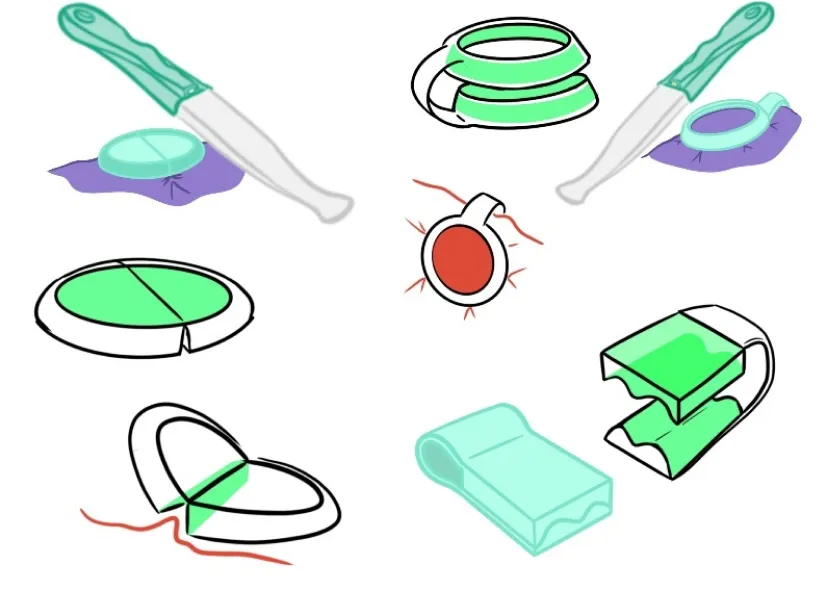

Our Industrial Designers worked with Latch Light to iterate on the design of the clip, suggesting potential designs that could hold the light more effectively and securely.

Our team iterated with new ideas and client feedback to identify the perfect clothes clip solution to use Latch Light handfree. Ultimately, the client favored a spring-loaded clip over a magnetic clip. Our team designed a custom spring clip with silicon-overmolded teeth and finger grips for added security and comfort.

The final design of the Latch Light spring clip provided a secure way to attach the light to the user’s clothing and use the light hands free during nursing.

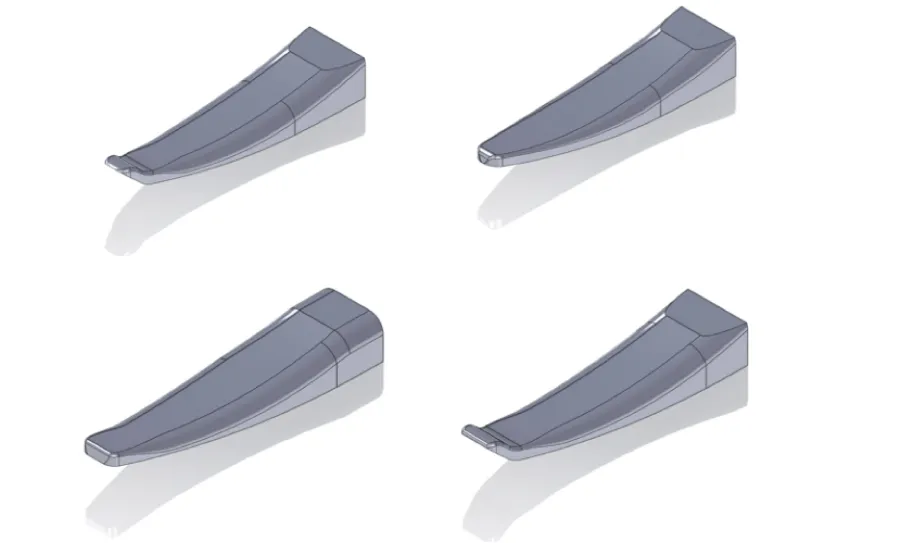

Our team also iterated on the design of the silicon tip, providing a variety of 3D printed options for latch light feel and present to their lactation experts for expert feedback. Ultimately one of these designs was selected to replace the previous and be included in the final product.

Form iterations of the silicon tip utensil were designed in 3D CAD and 3D printed to give the client a chance to feel and provide feedback. Ultimately on of these forms was used in the final product.

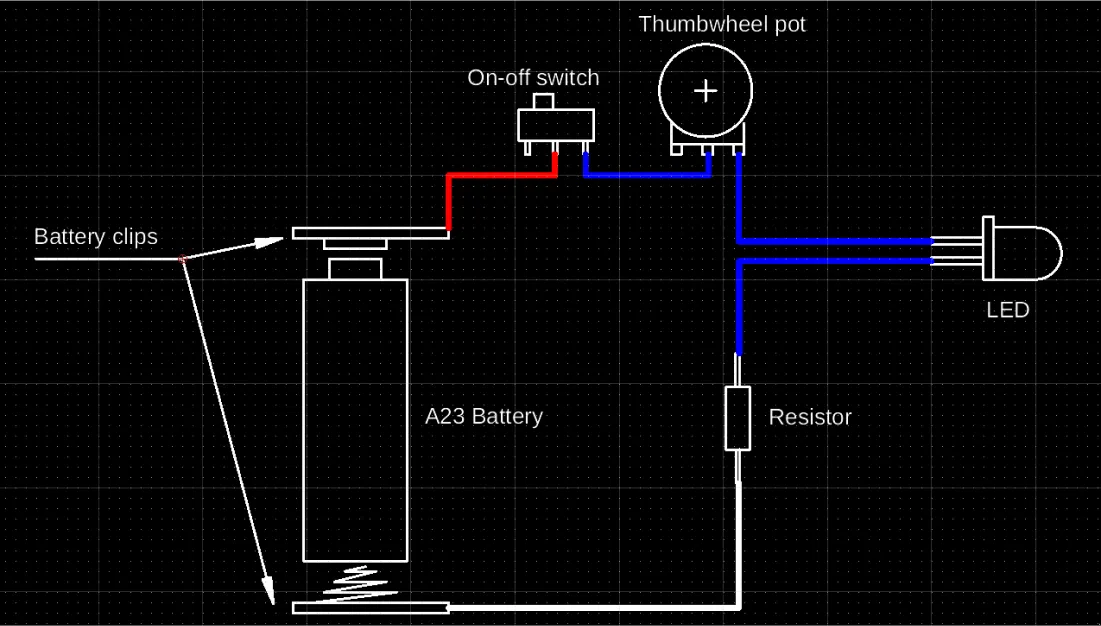

Our Electrical Engineers spec’d appropriate components for the flashlight, including:

A simple electrical schematic shows the electrical design of the Latch Light flashlight. A power switch and thumbwheel potentiometer were selected, allowing the user to switch power and adjust brightness independently.

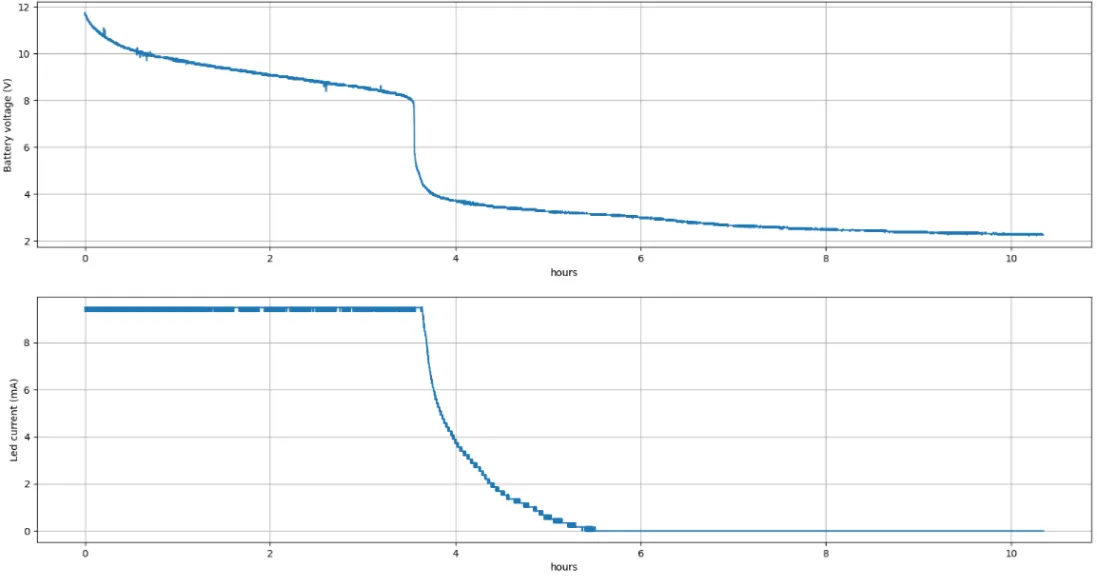

Our engineers selected the A23 battery as optimal given the client’s desired battery life and size requirements. We conducted electrical discharge tests to confirm the battery life in real use and observe how the depleting battery life affects the brightness of the LED.

Data from our battery discharge test with Latch Light’s new battery.

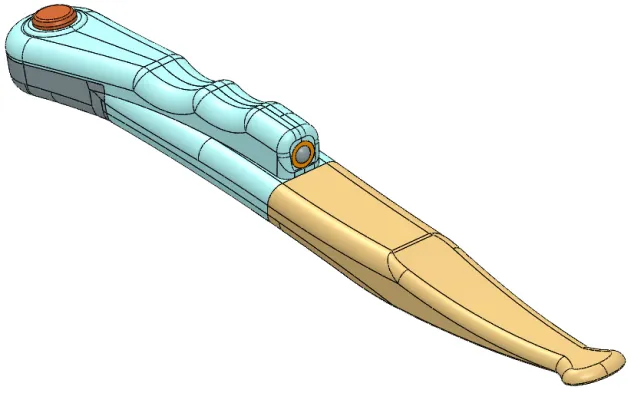

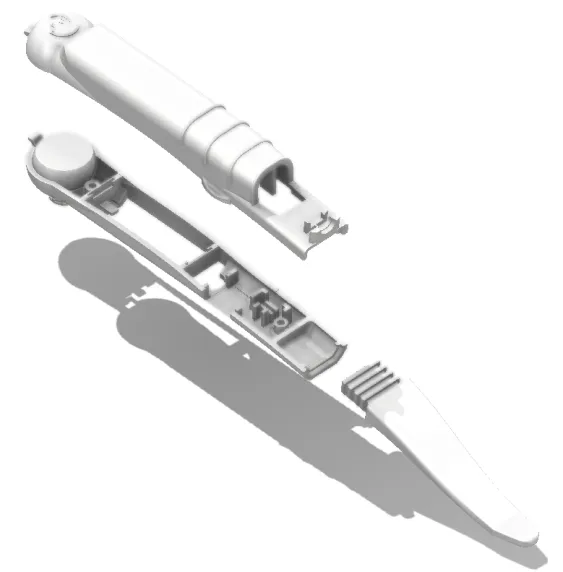

Our mechanical engineers fully redesigned the enclosure to change the direction of split from horizontal to vertical. This change eliminated the seam across the top of the device and the flashing associated with it, improving the tangible quality of the device.

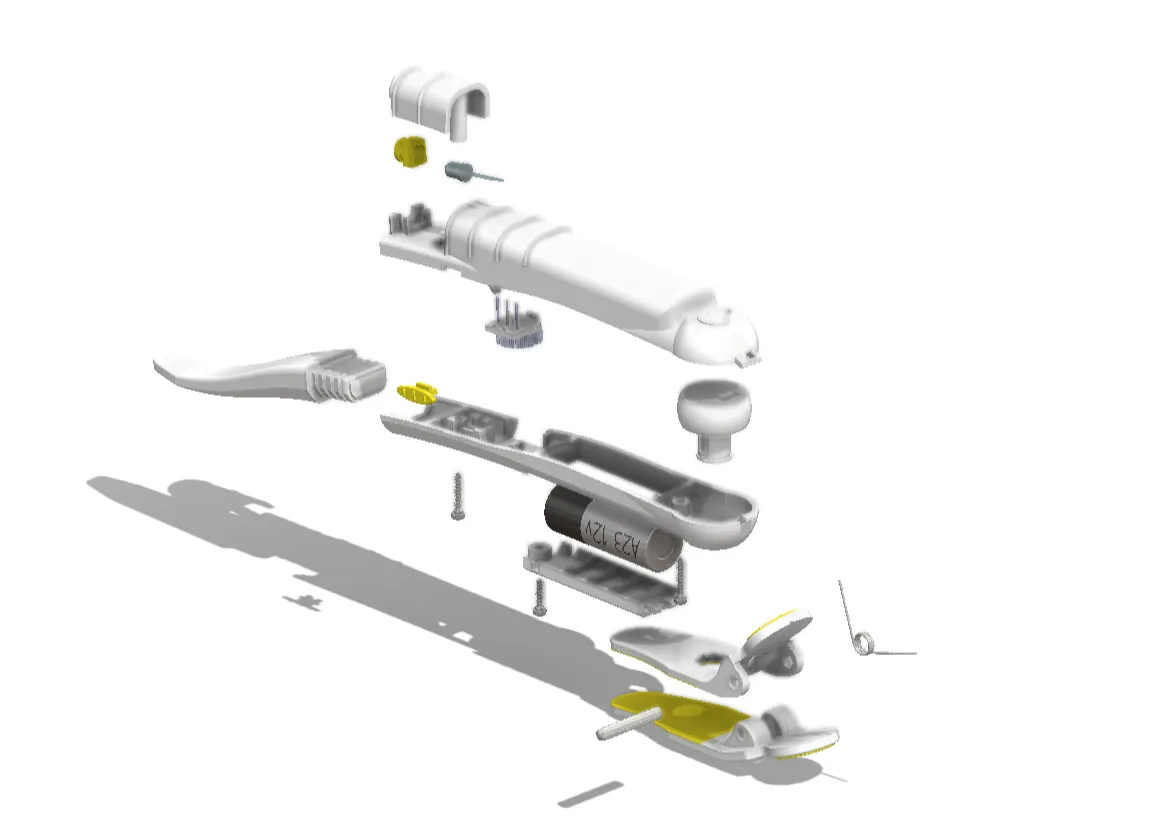

Our team also redesigned the interface of the silicon tip and the plastic enclosure to make the tip removable. This allows the user to separate the tip from the flashlight to put this part through the dishwasher without damaging the product.

To achieve the client’s directional adjustability requirement during hands-free use, our team designed a low-profile socket joint. This joint allowed the device to rotate on its spring clip by 300⁰ and tilt by approximately 50⁰.

An exploded view of the Latch Light’s redesigned enclosure shows how the enclosure was adjusted to spit horizontally for a higher-quality feel. This view also presents the removable silicon tip and the low-profile socket joint.

Our engineers redesigned nearly every component in the product’s assembly to optimize for injection mold tooling, cost-effective manufacturing, and easy assembly.

An exploded view of the Latch Light 3D CAD Models. Nearly every component in the assembly was redesigned to meet the project requirements and optimize for manufacturing.

Once the design was approved, our team drafted production drawings to industry standard. These drawings detailed the design and manufacturing tolerances of each component, including materials selection and surface finishes. These drawings, along with a comprehensive Bill of Materials and Electrical Schematic, comprised a complete Production Package.

Latch Light was able to effectively use this Production Package to procure a number of quotes from qualified factories and secure quality manufacturing samples.